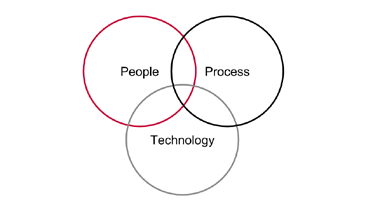

Operational Excellence manifests itself through integrated performance across revenue, cost, and risk. It focuses on meeting customer expectation through the continuous improvement of the operational processes and the culture of the organization. Operational excellence is building a sustainable competitive advantage through operations management which involves the synergy between People, process and technology.

KIAP works on a long term basis with clients committed to achieve operational excellence, some of our clients have been on the journey for years, improving performance year after year.

Our Approach to OPEX

The program is developed around a theme based on the business strategy and goals. The theme should be able to catch the attention of and create excitement amongst the employees while focusing on three critical dimensions.

- Customer Focused Process – Internal and External

- Consistent product & service while raising the bar regularly

- Complete comfort and delight of all stake holder – Employees, Investors, Business Associates, Government and Society

The entire movement is built on tangible themes like Position in the Industry, Best in class processes and practices, Quality Excellence, Delivery Reliability, Cost reduction, Productivity improvement, Workplace Improvement, etc. To sustain the movement and to ingrain the culture – KIAP also enables the organizations to challenge prestigious awards which will in turn challenge and motivate the teams while giving medium term results to the Business.

Key stages of this business transformation program can be represented as below

| Roadmap |

|

| Improve |

|

| Standardize |

|

| Sustain |

|

By the end of the program, the organization can expect the following outcomes

- Common goal orientation through all layers of the organization.

- Internal champions capable of managing implementation of improvement projects.

- Continual improvement spirit and concepts inculcated into majority of the employees.

- Significant process improvements completed giving substantial business benefits.